Latest Posts and News

Future Motion Inc. Launches Onewheel Flagship Trade-In Program

When to Change An Onewheel Tire [Wear Indicators]

Best shoes for Onewheel in (Complete Guide) 2024

New Traffic Regulations in Sweden Mandate Insurance for Electric Scooters

GT S-Series Motor Now Sold as Standalone Component!

Floatwheel Adv vs Onewheel GT – Who is the king?

Onewheel GT S-Series is Shipping – No Waiting!

How to Install Pint Footpads on a Onewheel Pint

In this article, we will show you how to install Pint Footpads on a Onewheel…

The New Pint (X) Flared Footpad and Alternative Options for Onewheel Enthusiasts

The Onewheel Pint has recently seen an exciting upgrade in the form of the Pint…

Onewheel Trade-In Program Terms And Conditions

Future Motion Inc. has launched a trade-in program for the Onewheel GT S-Series. This program…

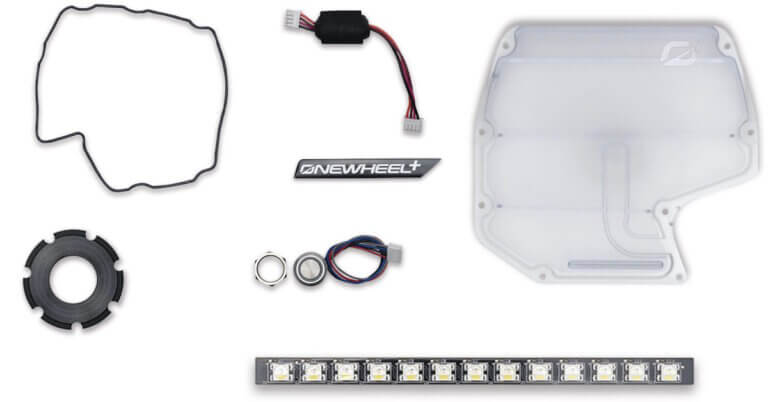

Future Motion Inc. Releases Spare Parts: A Milestone for Onewheel Enthusiasts

For years, the Onewheel community has been advocating for increased access to spare parts, and…

Future Motion Inc. Launches Onewheel Flagship Trade-In Program

In celebration of their 10th anniversary, Future Motion Inc., the company behind Onewheel, has unveiled…

LEGO Onewheel: A Masterpiece of Innovation and Creativity

This is the best LEGO Onewheel made today, a unique creation by the renowned LEGO…