One of the problems with running a Onewheel in a hot climate or up a steep hill is the risk of overheating either the battery or the motor. Overheating has not been a frequent problem with the XR but has become an increasing issue with the Onewheel GT. In the manual it’s stated that riding up a steep hill might overheat the Onewheel and void the warranty, this is a real issue.

The Onewheel GT is the most powerful board from Future Motions with its 3-horsepower. The downside with the upgraded battery, powertrain, and the increase in power of the motor is an increase in heat generation. Riders have had overheated boards indicating that the heat dissipation of the GT is not built to handle extreme environments. The XR, with less power, uses the same stator as the GT but hasn’t shown the same issues of overheating.

The Onerwheel GT has a built-in high-temperature shutoff to ensure that you are not damaging the board. This will limit you on a hot day or if you are pushing the board to the extreme. Here are some ways to reduce the risk of overheating the board.

All will void the warranty of your board as you will need to disable or modify the board in some way. Do everything at your own risk.

Badgerwheel Thermal kit

The thermal kit from Badgerwheel focuses on increasing the existing thermal dissipations that are already built into the board. Their test has shown that sanding down the coating increases the contact area and heat dissipation between the axle, axle block, and rail. This modification can drop the GT motor temps by 15 degrees F in hard riding conditions.

Doing this will require paint stripping, sanding, and leveling of mating surfaces of the axle, axle block, and rail.

A detailed guide can be found at Badgerwheel:

Badgerwheel GT Thermal Kit

Ferrofluid Inside The Motor

Ferrofluids are used to help transfer heat from the coils inside the motor to the magnets and hub. Cooling down the motor and also increasing the efficiency. This is done by bridging the air gap between the magnets and the stator (Read more about Ferrofluids here). This has been used in the bicycle community for a long time and now has come to the Onewheel community.

Armor-Dilloz is the first company to sell and market ferrofluid specifically for the Onewheel, as they have done with their Red Armor-Dilloz Onewheel Tire Sealant. Their new product is the ArmorChilloz FluxFluid a hydrocarbon-based ferrofluid that retails for $30.00, read more about ArmorChilloz FluxFluid. The Product has been shown to drastically reduce the heat of the motor and drop the temperature by several degree Fahrenheit.

While the manufacturer behind the product has given all assurances that this product is safe and suitable for Onewheels there simply isn’t sufficient specific data for us to be 100% confident in the long-term performance of this product inside the hub motor.

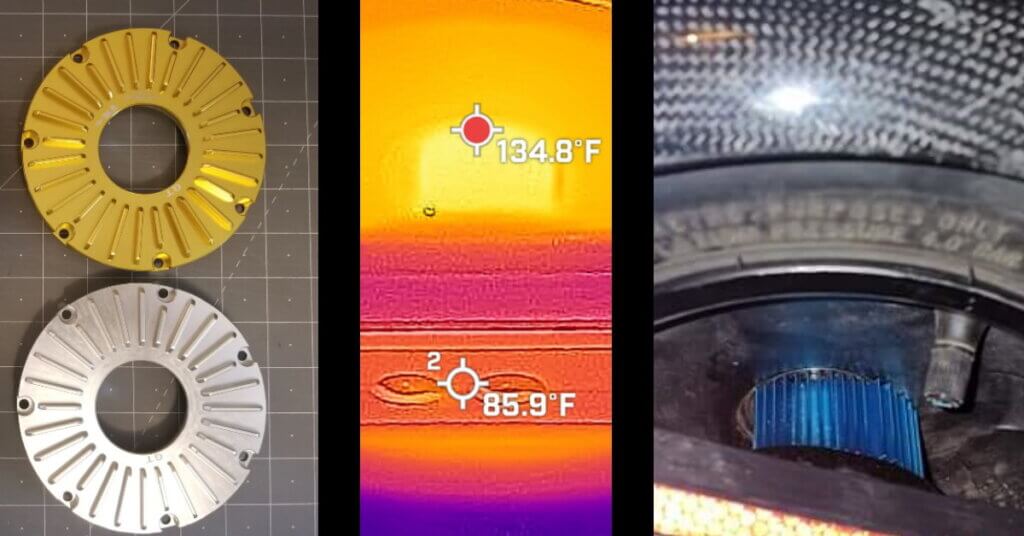

Replacement Motor Cover With Cooling Fins

Replacement motor cover with cooling fins on the outside to help with the heat. This is a collaboration with Tech Rails, Bob Nicholson (Bob’s Stoke Shop, SLS).

The motor covers are machined from solid 6061-T6 aluminum and are a direct replacement for the stock cast aluminum cover. Other benefits are that they are anodized rather than powder-coated to promote motor cooling.

Custom Motor Axle Blocks With Heatsinks

Tech Rails have been working on a more robust axle block that would address the heating issue at its root with a couple of benefits compared to the stock block. Not only do they increase the cooling with integrated fins they are also adding strength to the axle.

The axle carriers come with shims to use the stock GT wheel or the XR wheel on the GT and still be centered within the frame.

GT adjustable clamping axle carriers

Add Heatsinks To The Axle

Adding heat sinks to the axle has shown some great results to dissipate the heat from the motor. The sinks help with increasing the surface area and also are better located for airflow compare to the rails. Manu users have rail guards that decrease the heat dissipation from the board.

The setup uses aluminum heatsinks designed for small electric motors that get glued to the axle with thermal conductive glue.

Commercial Options

Land-Surf has developed their Onewheel GT axle heat sinks with the Stone Cold Chillers. The Stone Cold Chillers heat sinks will lower the motor temps by 20-30 degrees Fahrenheit (11,1-16,7°C).

Add Heat Sinks To The Wheel Disc

There is a user who has added heat sinks to the wheel disc with Steel Reinforced Epoxy, another option would be to pair it with thermal conductive glue. It’s reported to lower the Onewheel GT motor temperature by around 15-20 degrees cooler.

J-B Weld 8276 KwikWeld Quick Setting Steel Reinforced Epoxy

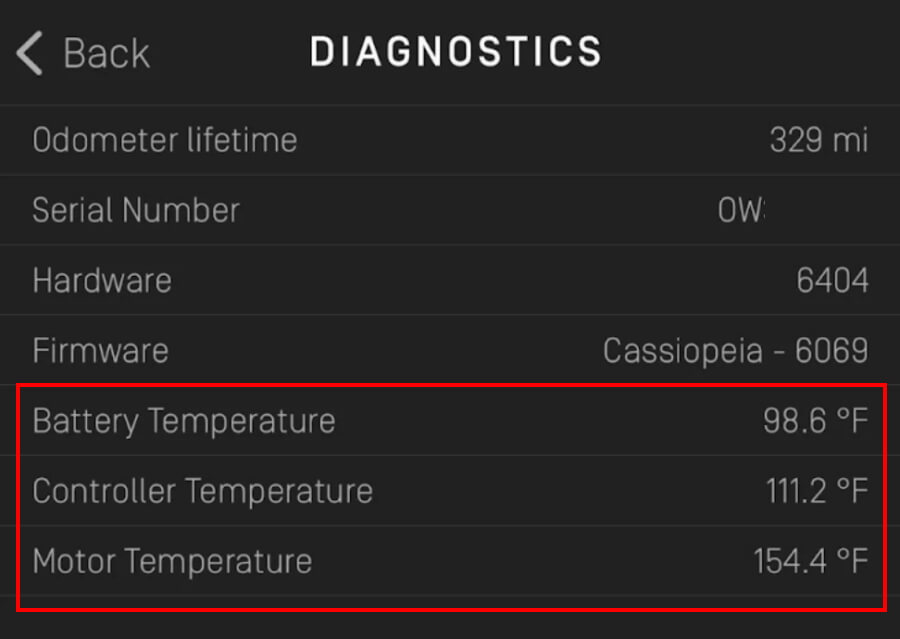

How To Check The Temperature

The Onewheel motor temperature, controller and battery temperature can be found in the diagnostics section of the Onewheel application.

- Battery Temperature

- Controller Temperature

- Motor Temperature

Overheating XR

There are reports of overheating XR, even if it’s not as common as on the Onewheel GT. Riders have reported that an overheated motor can make the motor squeak as the heat makes the metal expand a little, the result is a tighter fit on the bearings that caused the sound. Letting the board cool down will make the metal contrast and come back to normal.

The frame is designed to be used as a heat sink for the hub motor, where the heat is transported away with the help of the axle.

Disclosure: Some of the links above are affiliate links. This means that, at zero cost to you, I will earn an affiliate commission if you click through the link and finalize a purchase.